July 27, 2021

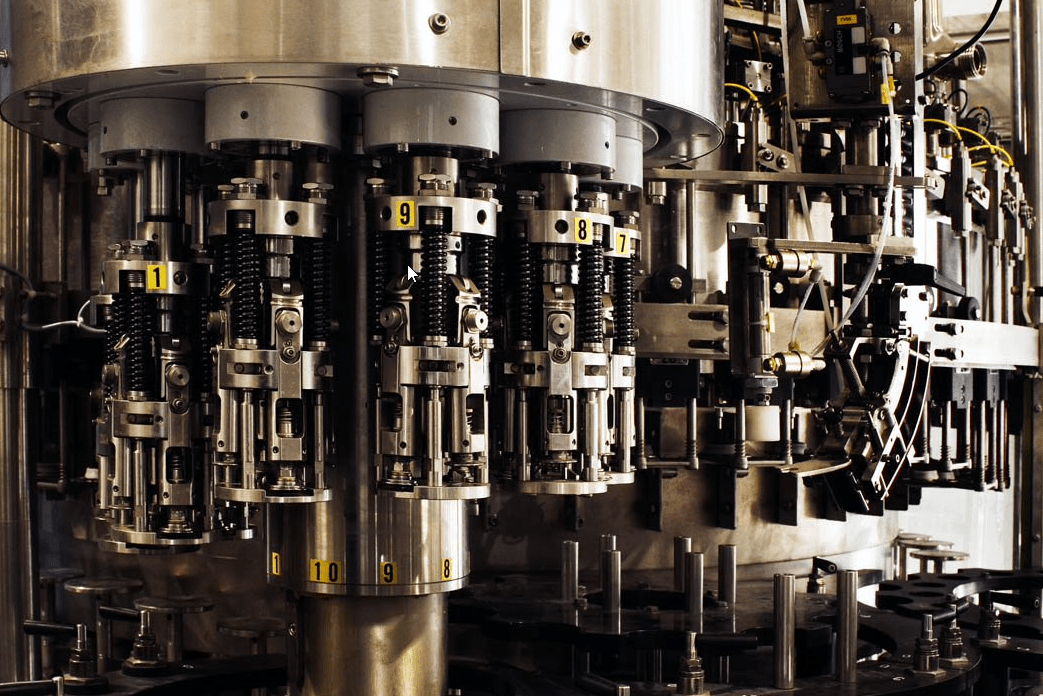

At WineWorks we are accepting the challenge to automate. This helps to keep our cost of service to the industry down, reduces the current challenges of finding labour and keeps our production lines working. That’s why we went to Facteon to bring Industry 4.0 technology to our production maintenance system.

Facteon offered a solution with the adoption of an IIoT (Industrial Internet of Things) software system specifically designed for maintenance which allowed us to streamline processes. Facteon was originally founded as the internal engineering division of Fisher & Paykel Appliances, and is now an international specialist in smart manufacturing and Industrial IoT technologies.

Moving from our old inhouse system, and three sites which also had slightly different processes and systems a significant advantage is that immediate cost savings were identified. Common spare parts used across the facilities are now more visible, and stored at a single location for centralised distribution thus reducing inventory levels.

The team is also able to schedule preventative maintenance. “The move to preventative maintenance was significant for a business which previously performed maintenance based on past trends. Despite WineWorks not regularly experiencing unexpected breakdowns, the team can now have greater confidence that all maintenance tasks have been completed on time. As a contract bottling company, the preventative maintenance element is particularly valuable as we can schedule maintenance during quieter periods” says Chris Brady, Engineering Manager at WineWorks Hawkes Bay.

The shift to preventative maintenance has also allowed managers on the factory floor to focus on high value tasks, rather than trouble shooting and manual analysis of past trends.

Furthermore, the system offers reassurance that all maintenance tasks have been completed on time and logged accurately. As many manufacturers will know, coordinating shifts poses challenges in regard to ensuring the accurate handover of information at the end of each shift. For that reason, the recording of maintenance tasks in real-time within a modern IIoT system ensures the information is available without delay across any device.

WineWorks has now implemented Industry 4.0 as a design standard. “Our long-term vision is to provide sustainable, cost-focused and safety-driven service that wine producers can trust to take their products to the world. For that reason, the world-class equipment we operate and the service we offer must be supported by Industry 4.0 and IIoT technologies”, says Chris.

WineWorks is continuously working to modernise our machinery and processes to ensure the delivery of a cost-effective and high-quality service. Backed by improved visibility over machinery performance and maintenance, we are now able to focus further on achieving incremental improvements across the three facilities.

You can read the full story from Facteon here.