May 23, 2020

If there’s one thing that the last few months have taught us, its that we need to have a plan B to get our products packaged and to shipping destinations such as Tauranga and Nelson ports, and the distribution centres of Auckland, Wellington & Christchurch. Modern management-speak for this is ‘supply-chain resilience’.

This has been a constant theme in the top of the South Island since the Kaikoura earthquakes. Not only were there a couple of big Seddon quakes (and one in Christchurch!) prior to that, but also flooding, slips, and ferry sailings have disrupted the flow of our products to market every couple of years, sometimes for months on end. And now, the mother of all disruptors, Coronavirus.

The global impact to supply chain and logistics as a result of Covid-19 is immense and will change the way goods are procured, produced, sold and moved. The New Zealand wine industry will be permanently affected, because our 3 main markets (US, UK & Australia) are at the end of a long supply chain. This chain is even longer if our wineries export unpackaged wine in bulk, as this adds layers of complexity and uncertainty to an already-fragile supply chain. In either case, it is important that supply out of Marlborough is maintained and scaled up to meet increasing global demand to keep our 5th-biggest export earner providing revenue for the country. After all, some 30,000 hectares of high-value wine, earning some $1.3 billion in exports from Marlborough alone is worth providing protection to in the form of a sustainable, competitive, innovative and resilient model.

The question is “How will we be affected and what can we do about it?”

Let’s focus for this article on the physical methods of getting the product to market (I’ll talk about IT automation in a later post)[1]. Our isolation and geography have given us a transport network that is 85% road.

- Road: moves our cargo to aggregated facilities such as distribution centres, depots and ports, but the government has been encouraging industry to invest in rail and coastal shipping to increase resilience and reduce cost and emissions. Marlborough in particular is very export dominant, and therefore requires access to infrastructure that can link this cargo to important supply chain gateways.

- Coastal shipping has become a reliable, cost effective and sustainable domestic transportation option, offering flexibility and resilience to supply chains, as Port Nelson, on top of its own direct shipping service es, can coastal ship to Napier, Tauranga and Auckland

- Rail continues to be heavily invested in by government for ongoing maintenance of costly infrastructure, but also to reduce freight traffic on roads. The connectivity rail offers is direct and generally reliable, however, due to New Zealand’s topography, climate and unfortunately frequency of natural events such earthquakes, rail is somewhat exposed to interruptions to service, as highlighted by the events post 2016 Kaikoura earthquake. But connections to Lyttelton and North Island ports are well-connected by rail

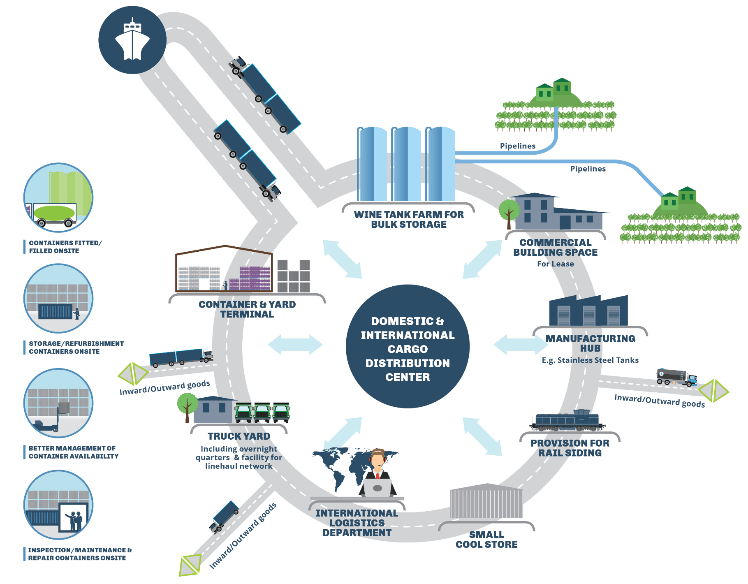

Since 2016, following the significant damage to infrastructure in the region, and disruption to supply chains at a critical period, WineWorks and its supply chain partners have been actively planning how to prepare for the next disruption. WineWorks other two plants have the capacity and ability to bottle if the other plant gets knocked out, so this offers a Business Continuity Plan for WineWorks clients. The linking solution is a state-of-the-art supply chain and logistics hub that can pivot to switch freight between road, rail and coastal shipping in case of a natural or man-made disaster. The site will comprise infrastructure and service provisions and is now ready for imminent development. This exciting development is a product of the ecosystem of support partners that are collaborating in order to meet the needs of the market, which is now resulting in this hub.

This hub will add value and resilience to the Marlborough region and the Top of the South Island. This value will be derived mostly from economies of scale through facilitating cargo in the region at this state-of-the-art multi-functional facility, reducing per unit costs. The wine industry will be the largest user and benefactor of this facility, which will also be complemented by other cargo types. The recently completed Strategic Review done by New Zealand Winegrowers concludes that there are only 5,000 hectares of commercially viable, productive land remaining in Marlborough, highlighting the need for us to focus on value enhancement and productivity, while maintaining quality. What this means is that we need to be a reliable supplier of quality wine to our clients worldwide. We cannot be making excuses every time we have an earthquake!

______________________________________________________________________________________________

[1] This is the first article in a series in which I explore other opportunities that WineWorks is developing to utilise IT automation such as pivoting our IT systems towards frictionless supply to the B2C space to assist our clients become more digital, and blockchain.