January 31, 2019

We all talk a lot about sustainability. We thought it was important to show you how WineWorks walks the talk. Sustainability is something that forms part of our ‘Lean Works at WineWorks’ values. Below you will find our actions & principles to be as sustainable as possible…

- Glass is collected by Metallic Sweeping, rough sorted, mixed with the glass from Council owned resource recovery centres, and kerbside recycling, then sent to Auckland for final sorting and processing into cullet (granulated glass for reuse in the manufacturing process) by Visy, who supply it to OI. OI’s Auckland plant uses around 70-75% recycled cullet in their operations, which makes them one of OI’s top three performing plants globally for recycling.

- Cardboard is collected by Metallic Sweeping, combined with resource recovery and kerbside material, and sold on the open market for reprocessing.

- Paper is collected by Metallic Sweeping, combined with resource recovery and kerbside material, and sold on the open market for reprocessing. This is sold as a mixed grade product for final use in packaging materials, so is able to include a higher proportion of otherwise unrecyclable paper product such as label backing.

- Plastic is baled and sent to Replas for reprocessing into slipsheets. The bales are moved as a backload on northbound trucks which would otherwise be empty or partially loaded, which reduces the overall environmental footprint of the process.

- Metals are collected from any source in the facility including Lunchrooms (steel and aluminium food and drink cans), engineering scrap, damaged or redundant equipment, caps from quality checking, obsolete customer cap stock, production wastage, and sold to local scrap dealers, either by being collected, or delivered via WWM Engineering team vehicle.

- Wooden pallets are repaired in the first instance rather than being disposed of. Pallets we cannot use are gifted to other businesses, sold to AzWood for production and distribution of biofuel pellets, given to clients for their own use, or donated to charities (eg logistics team championed a process of cutting kindling which was given to hospice for sale). Our pallets and wood packaging have also been used for such diverse purposes as building film sets for local movie production, or upcycling in shop fitout by local businesses.

The Principles we use to run are sustainability program are:

- We consciously NZ-based reprocessors to reduce carbon footprint of the recycling programme, all our glass and plastic is reprocessed in NZ, as is any wood.

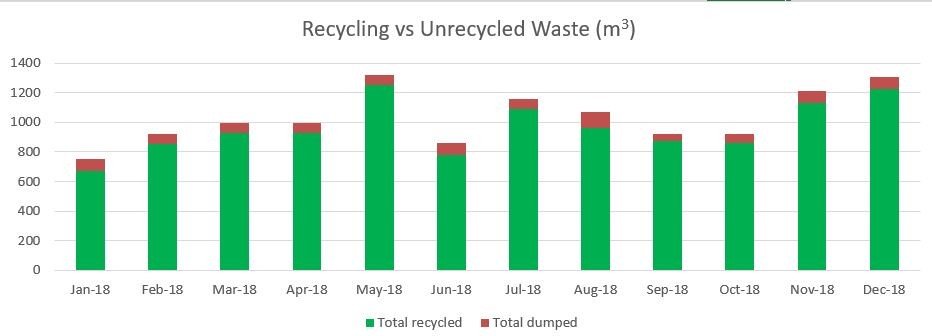

- All recycling and waste volumes are reported on monthly, any anomalies are investigated, and opportunities to improve or adapt are sought out. This chart shows the proportion of our waste that is recycled vs thrown out in our Marlborough plant over the last 12 months:

- Energy sources are low emission, with electricity being the predominant energy used throughout the facility, including for forklifts. LPG is used for hot water generation rather than higher emission diesel or coal. All energy used is reported on monthly, again any anomalies are investigated, and opportunities to improve are sought out.

- Industrial lighting has in the past 12 months been converted to energy efficient LED fittings, with 97% having been converted already. By close of calendar year 2018 all light fittings in WineWorks Marlborough will be either Fluorescent or LED.

- Where possible, we work with neighbouring businesses to improve Sustainability outcomes by sharing knowledge, skills, contacts and resources.

- WineWorks Marlborough is a key stakeholder in the QuayConnect model which optimises the flow of packaging materials (bottles in particular) into our facility and the movement of finished goods for export out. This programme won a Green Ribbon Award in 2017, and was a finalist for Large Energy User Initiative for the Deloitte Energy Excellence Awards that same year.